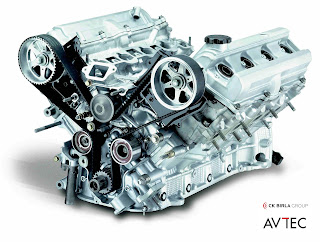

In the automatic transmission for commercial vehicles, there is no clutch pedal and gear shift lever

available. It has two planetary gear set which is folded together in a single

component and a various set of bands to lock its parts. In this, different gear

ratios are produced by a set of gears.

Main components of a planetary gear set are:

- The

Ring Gear

- The

planet gear along with the gear carrier

- The

sun Gear

The primary job of the automatic transmission in the commercial

vehicle is to operate the engine in order to allow it in the speed of narrow

range. It also provides a wide range of speed output.

Summary:

Sometimes it could be seen that the manual transmission for commercial vehicles could

not do the work of selecting the right torque and speed for the right load

which results in the poor utilization of the power. This could be done

perfectly by the automatic transmission.

The unit of automatic transmission also has an odd system which

is hydraulic and has control of the bands and clutches. A gear pump is also

present for the movement of transmission fluid all around. In order to lock the

other parts of the gear set, a set of three wet-plate clutches is also present

there.

http://www.avtec.in/avtec-automotive-engines-and-transmissions.php